| Norsk Megling & Auksjon AS | |

| Tollbugata 9, Bodo, Norway | |

| Contact: | Morten Larsos |

| Telephone: | Reveal Telephone Number |

| View All Norsk Megling & Auksjon AS Listings | |

Video

Description

Well-maintained Ro-Ro pax ferry built according to DNV regulations and later converted to Ro Ro passenger / cargo ferry. The vessel has been daily use utnil now and are ready for delivery. The vessel has in daily use and could bee inspected consecutively. Possibility to hire an independent inspector from a maritime consulting company or class company due to the Covid 19 situation. We also have the opportunity to assist with crew and sailing permits.

The annual passenger certificate renewal was done in september 2020. The vessel has an EU D certificate 25 nautical miles from land. The vessel has very good maneuvering properties and is equipped with Becker rudder, propeller nozzle and swivel propeller system. Furthermore, it has a 250 kw bow thruster with start and stop from bridge. Separate cargo area with keel of about 70 square meters. Load crane on top deck with hydraulic hatches down to the lower cargo room. Cargo 170 tons / 24 cars.Aft port:

Waterproof bulkhead door made of steel is top hinged and raised / lowered using a hydraulic jig winch mounted on boat deck. The folding is done using hydraulic cylinders built into port.

The gate is 6.52 m x 5.1 m, and the opening's light size is 6.4 m x 4.55 m.

The door is locked with hydraulically operated locking wedges in "Fully open" "middle" and "Lowered" position.The freshwater system consists of 2 freshwater tanks of 15.5 m3 each. Two hydrophore pumps suck water from these and deliver via pressure tank to users.

Specifications

| Vessel name: | Haarek |

| Condition: | Very good |

| Vessel type: | RO-RO Pax ferry |

| Builder: | Sandnessjoen Slip AS |

| Model: | Combi Car - Cargo- Pax |

| Constructed: | 1973 |

| Refitted: | 1993 |

| Registry: | NORWAY |

| Class Society: | Norwegian Maritime Administration ex. DNV |

| Class Notation: | DNV 1A1K ICE C |

| Cabins: | 7 |

| Heads: | 10 |

| No. of engines: | 1 |

| Engine model: | Bergen Diesel Rolls Royce |

| Engine power: | 1200 |

| Fuel type: | Diesel |

| Fuel Consumption: | 120 Litres Per Hour |

| Drive type: | Shaft drive |

| Cruising Speed: | 11 Knots |

| Maximum Speed: | 13 Knots |

| Nominal length: | 48.95m |

| Length over all: | 48.95m |

| Beam: | 10.7m |

| Hull material: | Steel |

| Hull colour: | Black |

| Fuel capacity: | 62000 Litres |

| Water capacity: | 75000 Litres |

| Holding tank capacity: | 60000 Litres |

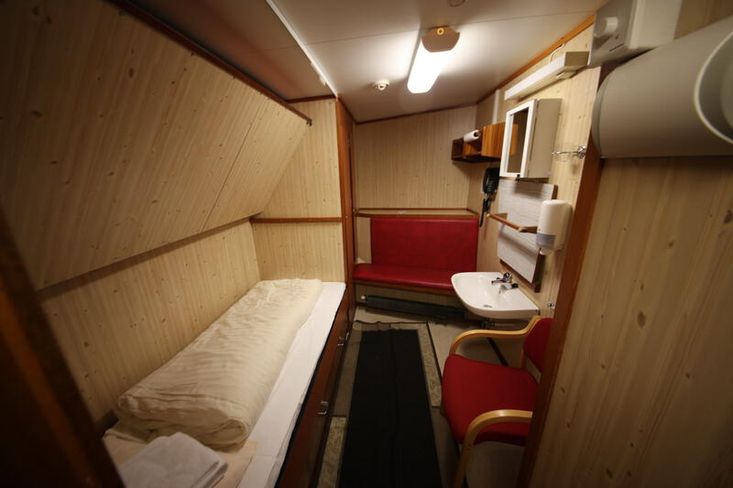

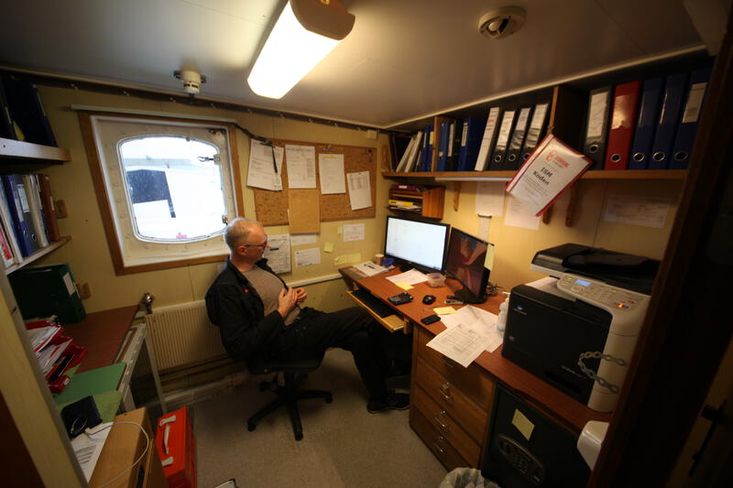

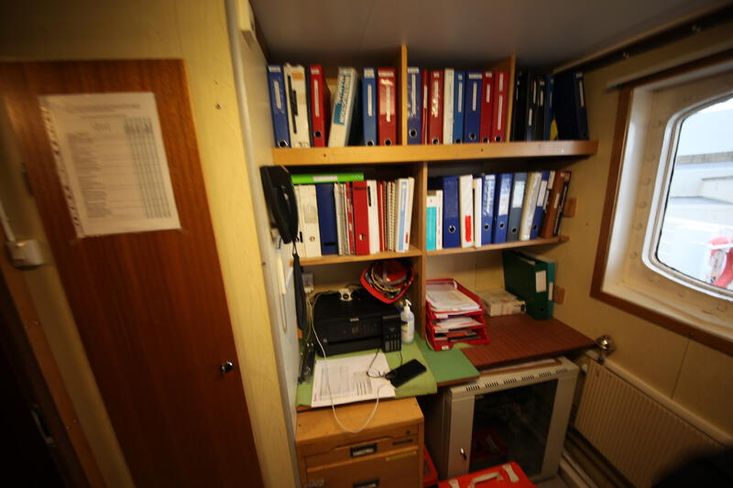

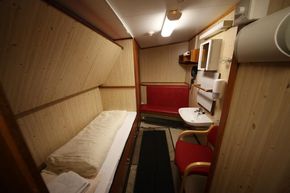

Accommodation

7 x cabins

5 x toilets

3 x showers

2 x Saloons

Galley

Cafeteria section

Crew room

Ticket office

3 store rooms

Office

Construction

Built: 1973 Sandnessjøen Slip , 1993 Rebuilt and extended to Ro-Ro pax ferry / cargo ship with cargo room and crane.

Modell The ferry was rebuilt in 1993 and is today a Ro-Ro combined cargo boat and ferry that can carry goods and cars. Today: 24 cars / 170 tonn deck cargo. Trading area 4 / 25 nautical miles

Tonnasje Gross register tonnes (nationally) 855.3 Net tonnage 420 Nationally security tonnage:

Length over all: 48.95 meters Width: 10.7 meters Maximum draft: 3.86 meters Axle pressure: 13 tons Cargo: capasity: 170 tonn

Capasity: Pax: 87 /100 Cargo: 170 tonn with cooling Cargo room with 2 x units with compressors Deck crane

Service speed 10,5 knop Max: 12 knop Diesel consumption around 130 liter in hour on 10 knot speed on regular route traffic. These with main engine, generator and all system.

2 x bottom water tanks 30.6 m3 2 x bottom water ballast 20.8m3 ex. diesltanks 2 x bottom water ballast 45m3 2 x bottom water ballast 38m3 2 x bottom fuel oil tank 26.2m3 1 x day tank engineroom 2m3. 1 x sewer tank cargo space 4m3 1 x roller dam tank 30m3 1 x waterproof bulkhead. Approx. In the middle of the boat (roll damping tank) All ballast water tank have always been filled with freshwater and ar in very good condition. Diesel capacity: 41.6 + 20.6= 62 m3

Equipment

The ship is equipped with Hydraulic loading / unloading crane, type MCV 1077-5 Tonn / 9 meter placed on the boat deck. Lifting capacity single Wire 2.5 T, double Wire 5 T. The crane can be controlled with wireless radio control.

Hydraulic Cargo hatch on top deck and on car deck!

Deck cargo: 170 tonn

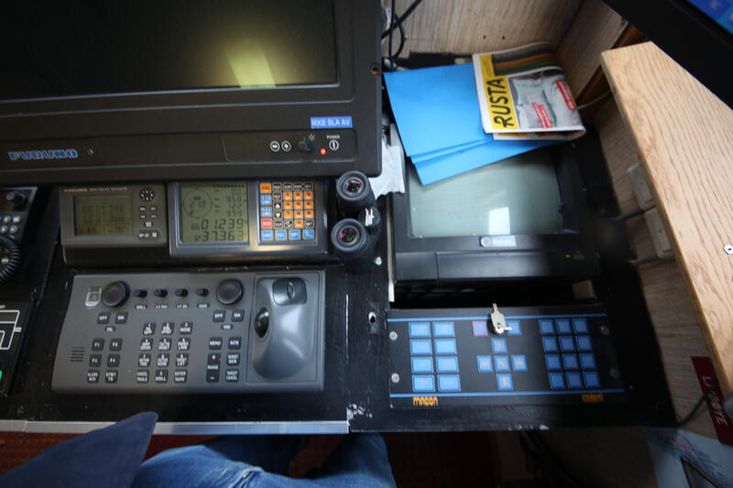

Navigation Equipment

Radar 1: Furuno 10 Cm Marine radar, Modell FAR – 21X7(-BB) SERIES

Radar 2: JRC radar 3 cm, type JMA-5312-6/6HS

Furuno GPS and Furuno FA 100, AIS. Anschutz Gyrokompass,

Magnet compass, Robertson autopilot, Simrad Ekkolodd.

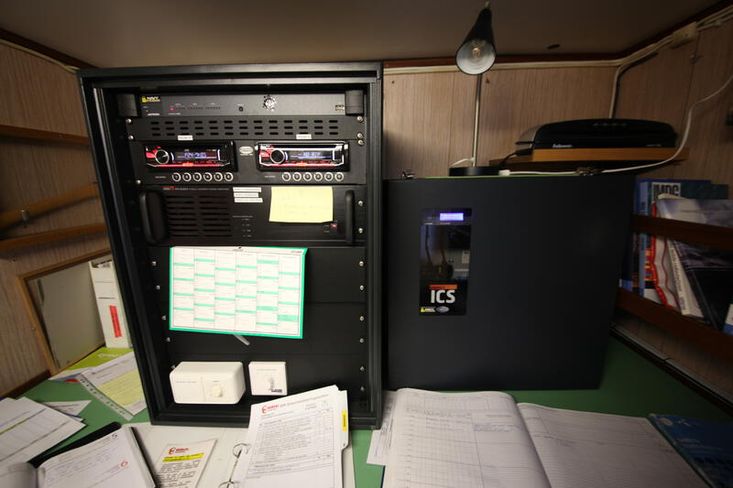

5 x portable UHF type Motorola GT 340 VHF: Sailor DSC: Sailor Mobile phone: Siemens 3 x Portable GMDSS SRH 50 Navtex SRH Tron Air helicopter radio Tron Sart radar transponder 2 x megaphone P117 Telechart 2023 Map plotter For internal communication on board is the Intercom Vingtor VMP 307. There are added cabins, offices, fair, galley, machine, lounges, hallways,car tires for / aft, boat decks, wheelhouses and to MES stations SB / BB.

Engine(s)

8-cylinder 4-stroke diesel engine made by: Nordmo, Bergen Diesel (Rolls Royce) type LMD 8 on develops 938 kw at 750 RPM. Gear system: One-stage reduction gear with 2.5: 1 gear ratio. Built-in servo motor in the secondary wheel and hydraulic clutch attached to the front of the primary shaft end. Pressure oil pump equipped with standard suction filter and retrofitted pressure filter. Type: Volda / Liaaen ACG 500 Volda / Liaaen HEG 500. Plant no: 150. Propeller: Pitc with 3 blades Was dismantled and controlled in 2018. Propeller head dissmantled and maintanced in 2018.

Auxiliary engines 2 x Perkins Mod 4.4 TWGM 1500, 75 kw at 1500 rpm. One brand new mounted now. Generator system 2 x Stamford generators, UCM 274C (1 stored), power 81.5 KVA. 50 HZ 230V

Engine for bow thruster: Volvo Penta type: TAMD 122 A Start and stop from bridge!

Pitch propeller: Brunvold 45 LTA 1225. 300 HP.

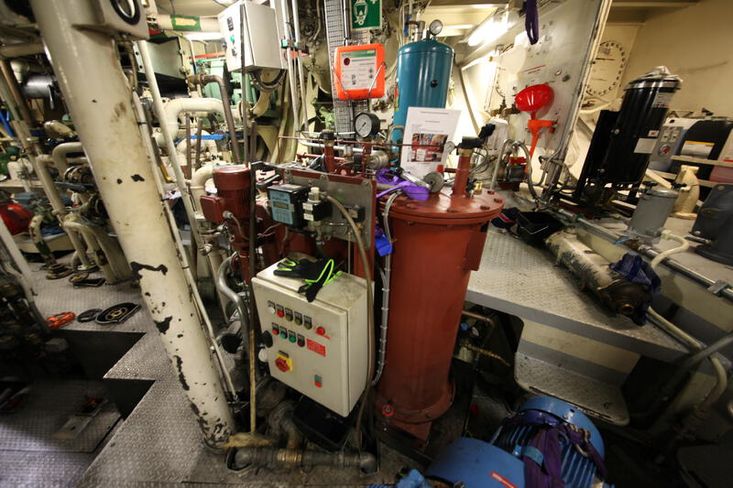

Sails & Spars

The lubricating oil system for the main engine consists of a sump tank outside the engine. An attached pump sucks oil from the sump tank and delivers oil to the engine via filter. The oil flows to the engine sump, where attached evacuation pump sucks off and pumps the oil back to the sump tank. It is also fitted an electrically driven evacuation pump that can be run in auto from engine swamp. A lubricating oil separator and CJC filter type HDV-27/108 which sucks from the sump tank, purifies the oil and delivers back to sumptank. The main engine has a separate lubrication system rocker arm. This consists of an attached pump that sucks oil from one tank of about 15 liters. The oil lubricates the rocker arms and flows back to the tank.

The gear has a separate system consisting of an attached pump that sucks oil from bottom gear and delivers oil via pressure filter to servo system and lubrication of gears.

The bilge system consists of four integrated systems. there are two ballast / booms pumps. An ejector driven by the pressure from the fire pump. The pump as used for filling the roll damping tank is connected to the bilge system. It best effect is achieved by using the ejector. The vessel also has installed a bilge water separator that has a suction side from the front and

aft edge of engine room. This delivers water / oil to the sludge tank.

The sewer system is of the type AQUACHEM BIO AQUA AEROB 25/50 SG.

The treatment plant is built for automatic operation and is approved in accordance with IMO MEPC2 (VI). Drains from toilets and sinks in toilet rooms are led into the sewer tank as is located in the cargo hold. When the tank is full, an audible alarm is activated on the bridge.

The fuel oil system consists of a bottom tank of 12 m 3 where the oil is pumped via an oil filter with water separator to a day tank. Return from this flows back to the bottom tank. Oil from the day tank goes to the main engine via filter to fuel oil pre-pump, which pumps the oil via fine filter to the fuel oil pump. Return, return to day tank. Fuel oil for auxiliary engines and boiler is removed from day tank and via filter on each motor to br.st pumps. Return goes back for day tank.

Electrics

Electrical system 2 x Stamford Generators 230V. 50HZ. 81.5 KVA. These can run in parallel on the main board. 24 Volt system. Electric start of auxiliary motors, 4 batteries placed on b.b. side aft of engine room Electric start of bow thruster motor, 2 batteries placed stb. page i engine.room - front edge on the side of the bow thruster motor. 6 x battery placed on wheelhouse roof for emergency power (4) and for VHF (2). Distribution center / fuse box placed in wheelhouse and leading edge mesh room and aft edge mesh room b.b. page. Charging rectifiers for emergency power and VHF batteries placed cutlery. Monitoring systems mai engine and aux, boiler are located in engine rooms and on Bridge. The fire alarm center is located on Bridge. The heating system Consists of one Pyro 104 kw central boiler with circulation pumps, radiators and batteries for heating fresh air, and heating of cooling water main engine.

Recreation Facilities (Toys)

Maneuverability and stopping ability

Load condition: No load.

Depth. Forut 2.5 m Aft 3.40 m

Bunkers: 62 m3

F.water: 30 m 3

Ballast: 140 m 3

Port maneuver: Speed ​​at start 11.7 knots

My speed 5.2 "

Rudder angle 40 degrees

Time v / 360 gr turn 120 sec

Diam. swing diagram 0.05 n.m

Length turn diagram 0.104 n.m

Starboard maneuver: Speed ​​at start 11.4 knots

Min "speed 5.2"

Rudder angle 40 degrees

Time v / 360 gr turn 114 sec

Diam. swing diagram 0.05 n.m

Length turn diagram 0.09 n.m

Port maneuver: Starboard maneuver:

0.05 Nm 0.05 Nm

0.104 Nm 0.09 Nm

Stopping distance: Speed ​​11.6 knots At 750 rpm

Stopping distance 0.121 n.m

Time 60 sec

The stop tests were performed with the rudder in the middle position.

NB It is recommended to reduce the speed to about 650 rpm, to eliminate the danger for "tripping" of main engine. The stopping distance will increase by about 40 m. 360 degree turn when using bow thruster, 0 speed and rudder in middle position: St.bord: 194 sec, 3 min 14 sec

Port: 223 sec, 3 min 43 sec

Safety Equipment

Bridge systems: Switching on and maneuvering the main machine is controlled via air-controlled man. levers on center control panel. Start / stop and travel of bow thruster via electric control on separate panel in starboard control panel. There are two systems for steering the ship, electric / hydraulic and hydraulic steering wheel.

Control system: The steering system on board is made by Tennfjord type: H-220-70.

The steering machine is operated from several positions in the wheelhouse. Steering can

also operated manually via the pump on which the steering wheel is mounted.

The maneuvering system: Engine and gear are maneuvered from bridge or engine room using

air pneumatics. It can also be maneuvered manually from the engine room.Mooring / anchor winches

2 x anchor winch w / enough placed SB/BB side front

1 x cable winch located cardeck BB side aft. Max. 500 kgRESCUE EQUIPMENT

Life jackets

Upper lounge, shelf over seats 63 adults

Upper lounge, shelf over seats 10children/5 baby vests

Boat deck, in box STB page 22 adult In cutlery 7 adults

Survival suits 5 life jackets in cutlery.

MES

The vessel is equipped with 2 MES rescue systems. Each system consists of slide and a 100 person fleet.

The systems are located on each side of the deckhouse on the boat deck

The systems are triggered from the stations, but can also be triggered from a bridge.

The vessel is equipped with 1 high-speed MAKO 651 MOB boat (sn:15181/2002) intended for 6 people located on the boat deck. The boat is powered by a water jet. MOB boat crane is NDA 25B Resque boat david IMO approved with loaded energy for death ship. (Build nr: 781)

Firefighting equipment:

There are 2 sets of firefighter equipment and 1 set of personal equipment on board, placed in fires 1 and 2 on boat decks.

Fire 1 (stores)

1 set of firefighter equipment w / 3 spare bottles + exercise bottle.

1 set of personal equipment.

1 piece. el. Drill w / 16 with more drills.

1 piece. extension pipe w / fog nozzle.

Fire 2 (red)

1 set of firefighter equipment.

Remote control

The following can be controlled remotely from bridge, start / stop bow thruster motor, Stand By generator, hydraulic pumps for bow door and anchor winches. Hydraulic pumps for bulkhead door, hatch and cargo hatch on car deck. Ventilation van car deck.

The vessel are in dry dock and yearly maintance on Slipen Mek AS in Sandnessjøen. The main 5 years certification was taken in 2018 and valid to 2023. The vessel has Becker Rudder and Proppel nozzle. Pitchable propeller. Please call Morten Larsos +47 90186230 or morten@auksjon.no

Certification

All details given in good faith but not guaranteed.

Copyright and Disclaimer © All images, video and text are copyright 2016 Norsk Megling & Auksjon AS. Content on this website is only for personal, non-commercial use and are not to be distributed. For any other purpose please contact morten@auksjon.no

Location Map

Note: Indicated location is approximate general area only.